Semiconductor Fire Protection Equipment

Complete, Engineered Fire Systems & Products

KFPI is a semiconductor fire safety company, 100% dedicated to semiconductor and related high-tech manufacturing process fire safety. Our global team is comprised of semiconductor experts who bring a diverse range of semiconductor technical expertise and a valuable depth of semiconductor process experience.

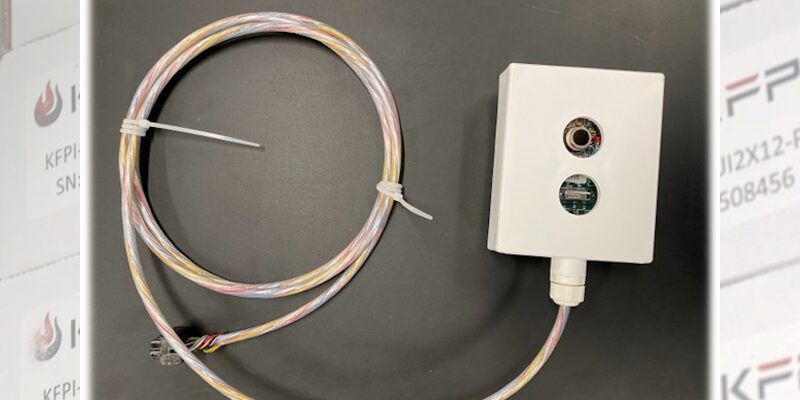

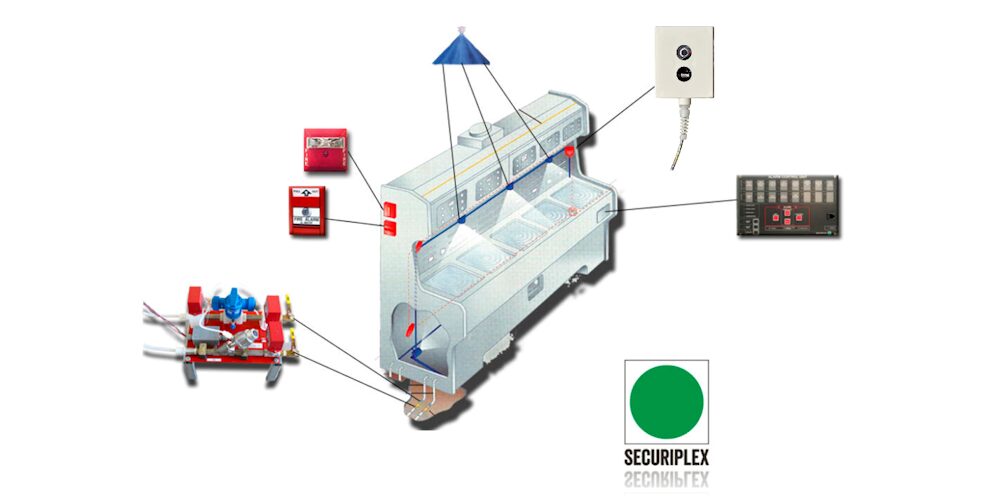

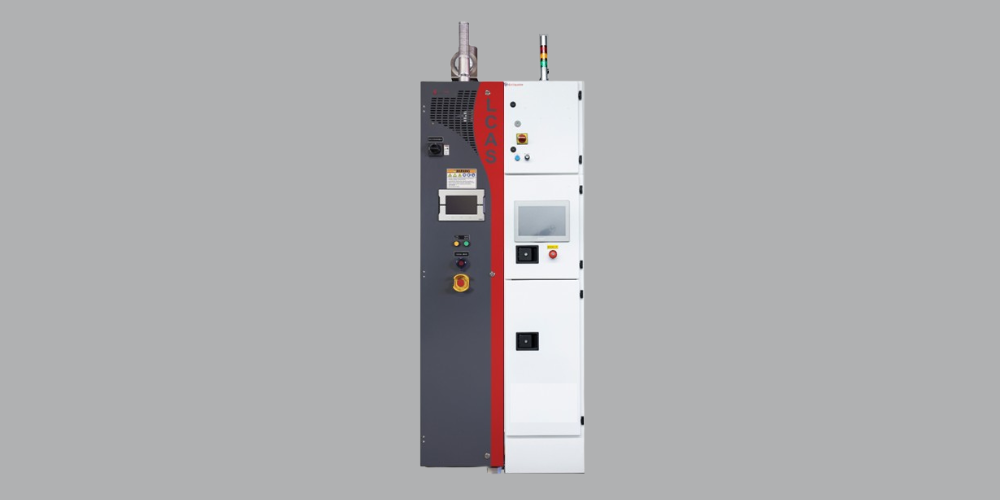

We focus on the small but critical industry niche of fire safety for process tools. KFPI does not manufacture fire suppression equipment. We use the best quality components in our designs of custom-engineered fire safety systems for semiconductor process tools.

About KFPI

KFPI is a semiconductor fire safety company, 100% dedicated to semiconductor and related high-tech manufacturing process fire safety. Our global team is comprised of semiconductor experts who bring a diverse range of semiconductor technical expertise and a valuable depth of semiconductor process experience.

At KFPI, we focus on the small but critical industry niche of fire safety for process tools. KFPI does not manufacture fire suppression equipment. We use the best quality components in our designs of custom-engineered fire safety systems for semiconductor process tools.