Semiconductor & Cleanroom Applications

LCAS – Leak Containment & Abatement System

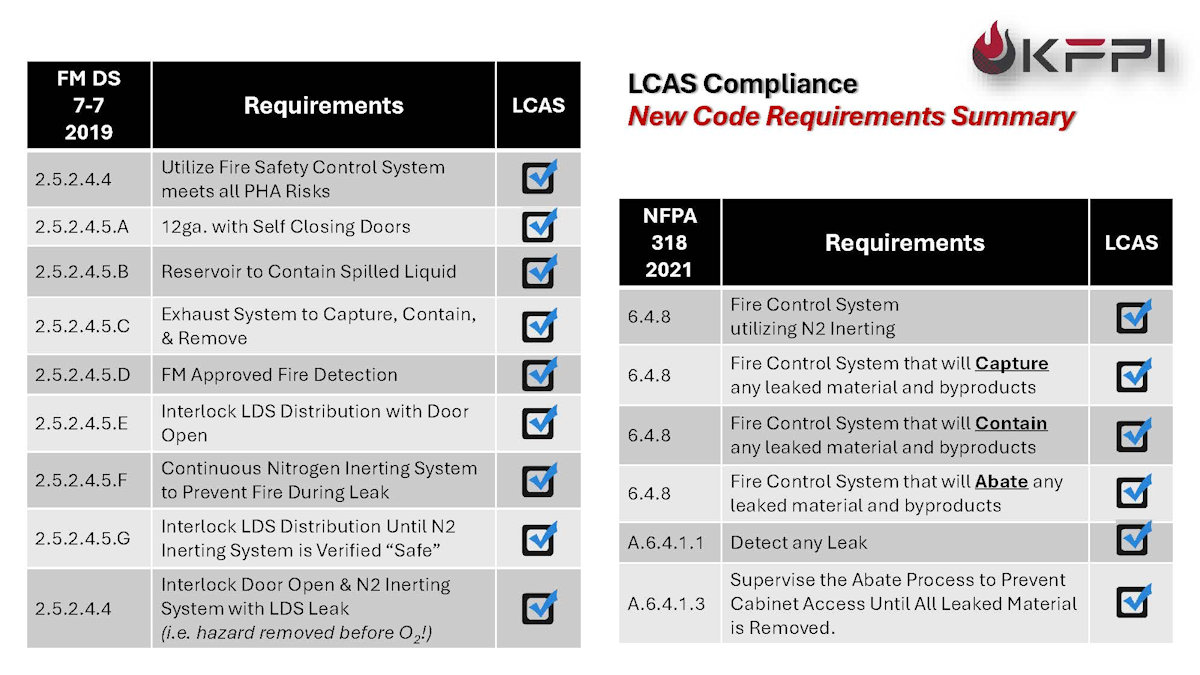

LCAS is a fire safety system for semiconductor pyrophoric chemistries / metalorganics storage and delivery systems. After years of R&D, performance testing, and safety compliance reviews, we have a perfected safety product. LCAS is a fire safety device, designed specifically to address the considerable fire hazard presented to semiconductor production by energetic materials. LCAS monitors bulk distribution systems for pyrophoric metalorganic materials, and in the event of a leak, safely contains and abates the metal organic material without fire, smoke, or particulate damage to semiconductor tools, processes, or clean rooms.

LCAS Features

- Safely Mitigates MO Liquid or Vapor Leak

- All Leaks are Contained and Controlled

- All Leaks are Safely Abated

- Isolates MO from O2 Incompatibilities

- Integrated Safety Controls, Detection, & Interlocks

- SEMI S2 / S30 Compliant

***We used Trimethylaluminum as our baseline chemistry for research and development testing. Other pyrophoric metal organics are presently being tested for abatement performance.