Semiconductor & Cleanroom Applications

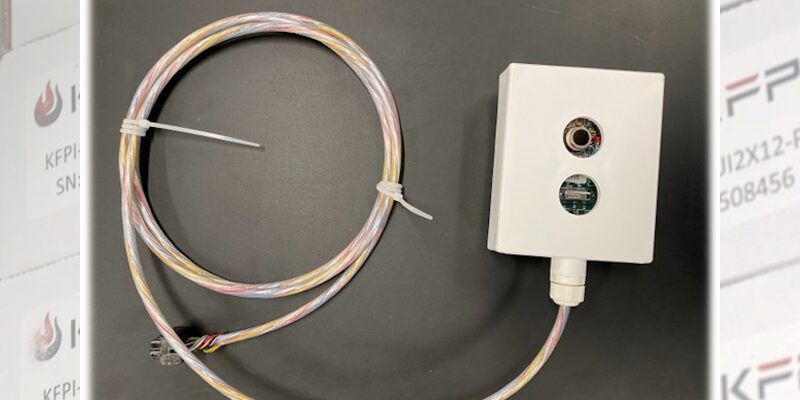

Flame Detectors for Semiconductor Tools

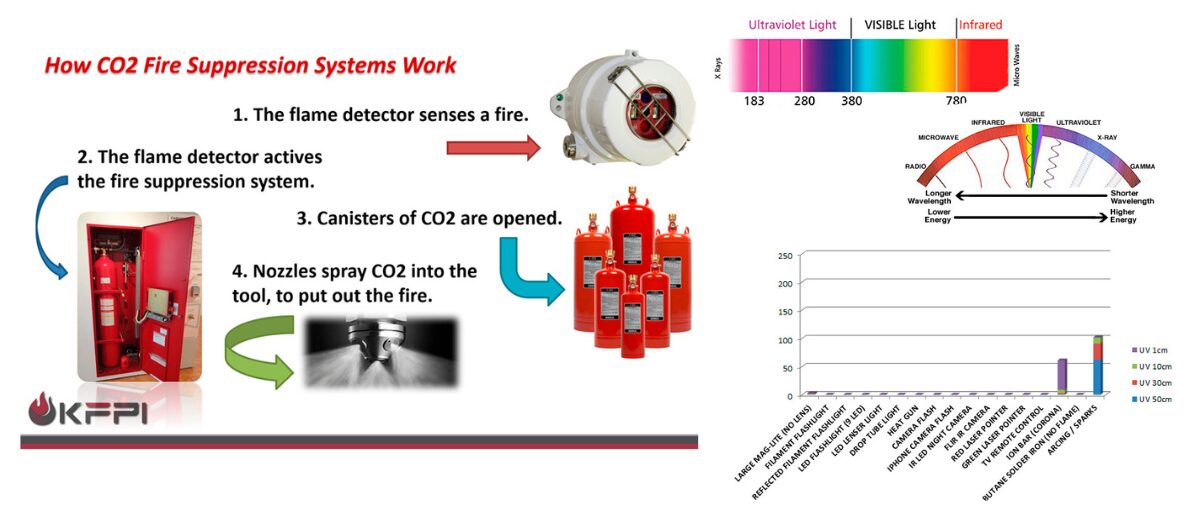

Fire safety systems designed to protect semiconductor manufacturing equipment typically use flame detectors to alert the presence of a fire in a semiconductor tool. These critical devices are a very important part of a semiconductor equipment fire suppression system. There are many different kinds of flame detectors, and it is important to use the right kind of flame detector, and to have it installed in the right place in the tool. Flame detectors are designed to see the heat signatures that are created by flames.

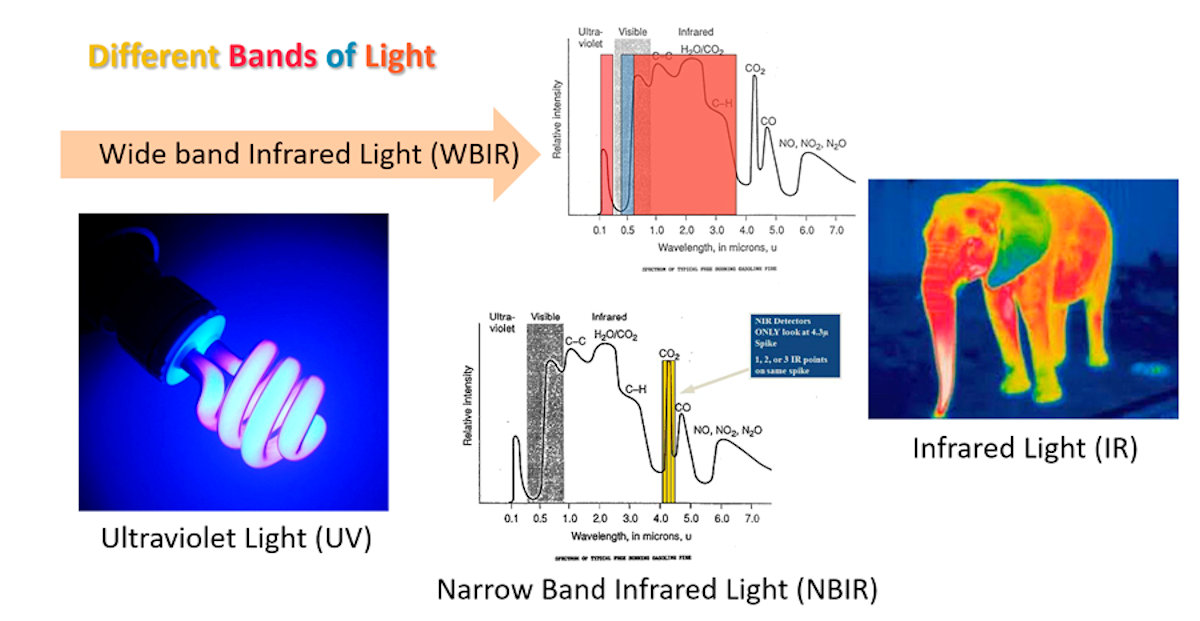

Different fuel sources create different flame signatures. It is important that a fire safety system is designed with a flame detector that can see potential flame signatures fueled by the respective chemistry in a semiconductor process tool. Furthermore, a good flame detector can distinguish between a fire and other types of light and heat sources such as a flash light or welding gun.