Article: Semiconductor Metalorganics

Metalorganics in Semiconductor Manufacturing

High purity metalorganic precursors are widely used in semiconductor manufacturing, in the production of integrated circuits and devices. These once exotic chemistries are now a standard part of various doping and deposition processes. Semiconductor-grade metalorganics are highly-refined for use as precursors in silicon and compound semiconductor industry processes.

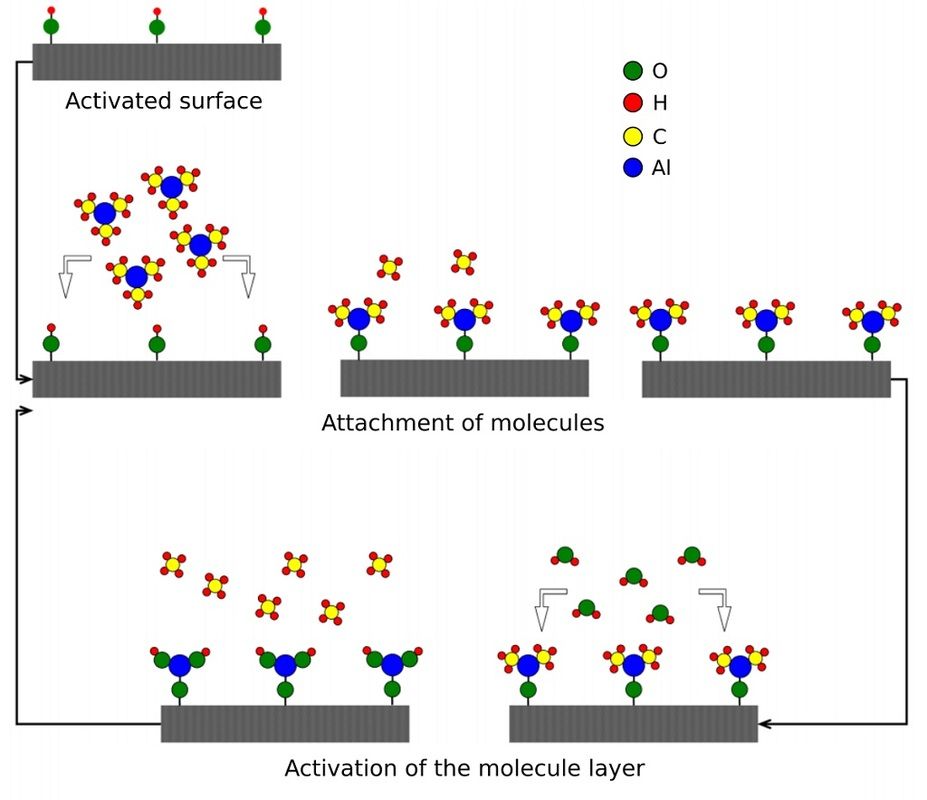

One of the semiconductor manufacturing processes that utilizes metalorganic precursors is atomic layer deposition (ALD). ALD is a thin-film deposition technique which is based on the sequential use of a gas-phase chemical process; it is a subclass of chemical vapor deposition (CVD). The majority of ALD reactions use two chemicals called precursors. These precursors react with the surface of a material, one at a time in a sequential, self-limiting, manner, and form precise patterns of micro and nano circuitry architecture.

Some of the common metalorganics used in semiconductor manufacturing are:

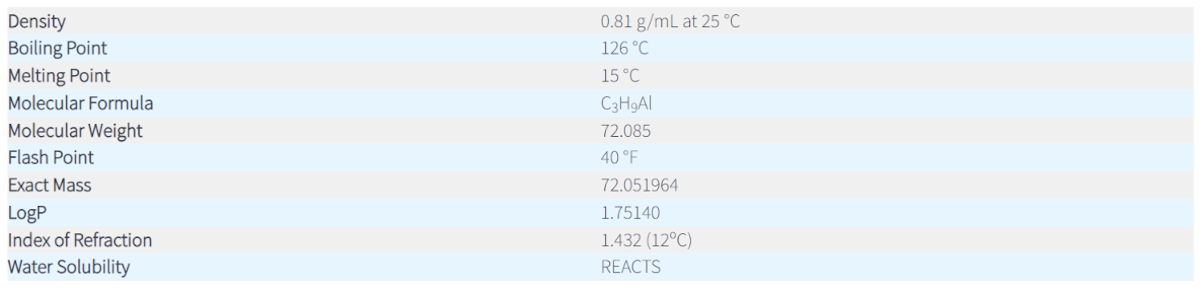

- Trimethylaluminum – TMAL

Precursor for solar cells and silicon substrate semiconductor production

- Trimethylgallium – TMGa

Precursor for the compound semiconductor industry

- Triethylgallium – TEGa

Precursor for the compound semiconductor industry

- Trimethylindium – TMIn

Precursor for the compound semiconductor industry

- Dimethylzinc – DMZn

Precursor for the compound semiconductor industry

- Diethylzinc – DEZn

Precursor for thin film solar cells and silicon substrate semiconductor production

- Bis(cyclopentadienyl)magnesium – Cp2Mg

Precursor for silicon substrate semiconductor production

Trimethylaluminium

Chemical & Physical Properties

Hazard identification

Classification of the substance or mixture

Pyrophoric liquids, Category 1

Substances and mixtures, which in contact with water, emit flammable gases, Category 1

Skin corrosion, Category 1B

Metalorganic Fire Safety

Many of the metalorganic chemistries used in semiconductor manufacturing are pyrophoric. Pyrophoric materials react with exposure to oxygen, and will ignite when they contact water or air. Pyrophoric liquids, solids and gases are materials that may ignite or react violently when exposed to air. These chemicals do not require an ignition source other than oxygen. They can erupt into violent flame, simply by introducing them into an oxygen-rich environment. They must be stored and handled in hermetically sealed containers or in inert (non-reactive) gas environments such as atmospheres of argon or nitrogen. Class D fire extinguishers are NOT capable of dealing with pyrophoric fires. Pyrophoric fires can be temporally be smothered, but will react immediately upon renewed exposure to oxygen.

SEMI EHS guidelines mandate extreme caution in the storage and handling of pyrophoric materials in semiconductor manufacturing. There are strict guidelines for safe use of these energetic materials, including a recommendation for utilizing a leak containment and abatement system (LCAS) to safely monitor safe containment of bulk chemistries, and to robustly abate all bulk chemical supply leak scenarios.

Specialized Metalorganic Safety Expertise

If your EHS concerns include the proper storage and handling of metalorganic chemistries, know that KFPI shares a common goal of preventing global semiconductor EHS hazardous events. Please feel free to reach out to us with any of your questions or safety requirements involving metalorganic chemistries.